EMAX High Energy Ball Mill Retsch

The Emax is an entirely new type of ball mill for high energy milling. The Emax combines high friction and impact to create extremely fine particles.

WhatsApp)

WhatsApp)

The Emax is an entirely new type of ball mill for high energy milling. The Emax combines high friction and impact to create extremely fine particles.

Cost economic grinding media balls for mines and minerals processing industries from AIA Engineering Ltd.

The Planetary Ball Mill PM 200 is an excellent choice when a high degree of fineness is required. Grinding down to the nano range. Read more.

CEMENT GRINDING OPTIMISATION Dr Alex Jankovic, Metso Minerals Process Technology AsiaPacific, Brisbane, Australia email: metso

Check Your Balls. Here are all the elements you should check to see if you have a ball from a ball mill or a genuine Napoleonic British cannon ball.

2 HPGR High pressure grinding roll for the minerals industry Introduction During its relatively short history in minerals processing, HPGR technology

Wear Resistant grinding media and grinding balls for cement plants from AIA Engineering.

International journal of advanced scientific and technical research Issue 4 volume 1, JanuaryFebruary 2014 Available online on ...

Ball Mills Ball Mills, and other forms of tumbling mills such as tube mills, rod mills and batch mills form a significant type of equipment used for the size ...

Exporter of Grinding Media Cylpebs, Forged Steel Grinding Media Balls, Hyper Steel Grinding Media Balls and HiChrome Grinding Media Balls offered by Mufaddal ...

SWECO VibroEnergy Grinding Mills are the most versatile line of mills available today for fast, lowcost particle size reduction to submicron range.

Engineering, products, systems and services for the cement materials producing industries.

watch 4 minutes video, and you will learn the basics of the ball mil for more information about the whole grinding process ( very long article it may take 35 ...

Cement is the basic ingredient of construction and the most widely used construction material. Its manufacturing includes extraction, proportioning, grinding,

RSG Inc, located in Sylacauga, Alabama specializes in fine powder technology. The company manufactures air classifiers, ball mills and stirred media mills for ...

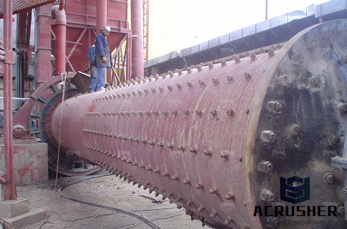

The ball mill is a key equipment to grind the crushed materials, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal ...

The High Chrome Grinding Ball manufacturer supplying for all the Japanese cement and mining plants. The PREFERRED Global supplier for LAFARGE, HOLCIM ...

Grinding media. Grinding balls are only one type of grinding media. Grinding media are the means used to crush or grind material (cement, mineral, .) in a mill.

Cement grinding Vertical roller mills versus ball mills Soeren Worre Joergensen MSc, General Manager, Engineering, Grinding Technology

Photo of a series of ball mills in a Copper Plant, grinding the ore for flotation.

How is cement manufactured? Learn cement manufacturing process thoroughly.

We produce a wide range of highalumina cements and calcium aluminate have customers in more than 60 countries around the world.

Cement is a binding agent and is a key ingredient of the most used manmade material: concrete. The demand for cement is strongly correlated to the rate of economic ...

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory ...

WhatsApp)

WhatsApp)