Ceramic engineering Wikipedia

Simulation of the outside of the Space Shuttle as it ... Ceramic engineering is the science and technology of ... Impact mills include the ball mill, ...

WhatsApp)

WhatsApp)

Simulation of the outside of the Space Shuttle as it ... Ceramic engineering is the science and technology of ... Impact mills include the ball mill, ...

Advances in Materials Processing IX: Research and Development of Four Axis Linkage Grinding Simulation System of BallNose End Mill

Roll Mill Schematic Diagram Of Ballmill. ... discrete element simulation of . three roll mill prize; ball mill catalogue CGM ... ceramic ball mill,ceramic ball mill ...

CFD MODELLING OF A STIRRED BEAD MILL FOR FINE GRINDING ... simulation of these mills offers a means of understanding ... which are normally steel or ceramic .

Iso Grinding Ball Mill,Portable Super Fine Powder Grinding Machine /ore Ball Mill For Sale, Find Complete Details about Iso Grinding Ball Mill,Portable Super Fine ...

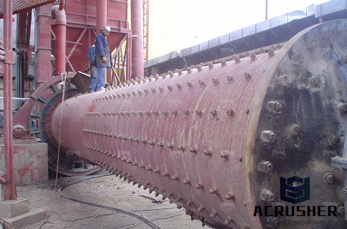

Rotary Kiln Combustion and Process Simulation. We are a professional Rotary Kiln manufacturer, that provides research and consulting services for Rotary Kiln ...

Rotary Kiln Innovation. The Cement Rotary Kiln, Lime Kiln, Metallurgy Kiln, zincoxide and ceramic sand kiln are made by us. Our Rotary Kiln is the main equipment for ...

ball milling of ceramics [ 3522 Ratings ] The Gulin ... ceramic ball mill simulation | Mining World Quarry. Ball mill Wikipedia, the free encyclopedia .

The MSKSFM14 is a heavy duty roller mill designed for the crushing, grinding, dispersion, and emulsification of metals, nonmetals, organic materials, herbs, and ...

Piezoelectric Ceramics Characterization ... A vibratory mill may be used rather than a conventional ball mill; ... the ceramic is processed to useful devices; ...

New Concept Projects formed a Joint Venture Agreement with Osborn and now supply the new Osborn Grinding Mill Range. Our capability includes the supply of new mills ...

Multotec SAG Mill Liners rubber composite lining components with the Hardox or casting inserts providing impact and wear resistance.

Simulation studies on Energy Requirement, Work Input and Grindability of Ball Mill Abanti Sahoo ... required in separate grinding of ceramic raw materials than

Ceramic engineering Wikipedia, the free encyclopedia. Ceramic engineering is the science and technology of creating objects from inorganic, nonmetallic materials.

Simulation and experimental research on Si 3 N 4 ceramic grinding based on different diamond grains

Ball size distribution is commonly used to optimise and control the quality of the mill product. A simulation model combining milling circuit and ball size ...

Correlations for the Grindability of the Ball Mill ... ceramic pellets or ... grinding rate and product size distribution from mills await the development of a simulation

Mill Speed Critical Speed. Mill Speed . No matter how large or small a mill, ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar rolling mill ...

Planetary ball mills feature attractive properties, like the possibility of dry or wet operation, straightforward handling, cleanability and moderate costs.

Analysis of Grinding Rate Constant on a Stirred Ball Mill Using Discrete Element Method Simulation. ... the forces acting on a ball and ... Ceramic Technology, 2011 ...

a ball mill simulation program, called PSUSIM. ... Ipek et al. Grinding of ceramic raw materials by a standard bond mill: quartz, kaolin and Kfeldspar. Grinding tests

PARTICLE BASED MODELLING OF MECHANICAL ALLOYING BY PARALLEL MONTE CARLO METHODS Roland Reichardt, Fred Weinhold and Wolfgang Wiechert Department of Simulation

ceramic ball mill simulation Mining World Quarr,Ball mill Wikipedia, the free encyclopedia . A ball mill is a type of grinder used to grind materials into extremely ...

Grinding in Ball Mills: Modeling and Process Control ... The design of a ball mill can vary significantly depending on the ... • ceramic balls with regular or high ...

WhatsApp)

WhatsApp)