Iron Powder Manufacturers and Distributors Find .

SM1001 is a high purity soft iron powder for making soft magnetic components using P/M method or resin ... CIRON is cast iron powder with about 95% iron content.

WhatsApp)

WhatsApp)

SM1001 is a high purity soft iron powder for making soft magnetic components using P/M method or resin ... CIRON is cast iron powder with about 95% iron content.

The iron ore ... loose powder particles. To turn it into a magnet, ... i thought the process of making a permanent magnet is such a complex one ...

The production of iron or steel is a process consisting of ... C so that it decomposes to form pure iron powder. ... of stainless steel used for making ...

Making Metal Powder. The first step in the overall powder metallurgy (PM) process is making metal powders. There are four main processes used in powder production ...

The Powder Metallurgy Process. Powder ... Virtually all iron powders for PM structural part production are manufactured using either the sponge iron process or ...

Materials » Ferrous Powders » Iron Powders » Iron Powder Reduced Iron Powder Reduced ; ... Description of the manufacturing process: water atomisation ...

The powder used for the process is a ... Iron phosphate coating gives minimum sludge formation and hence smoother ... thus making the process time effective.

Water Atomized Fine Powder Technology ... oxygen content of an iron based powder with small ... the exacting balance and/or control of process variables

Mar 07, 2015· Video embedded· Make Your Own Ferrite to Improve Magnetic Fields ... Fine iron powder is ... The process is pretty simple, like making a cake mix but a complete ...

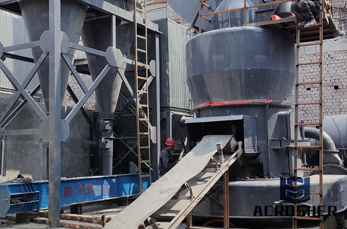

Iron Making Process, ... sodium silicate manufacturing process quick lime manufacturing process pig iron making process blast furnace iron making process tea powder ...

The sponge iron powder process or more precisely the solidstate reduction was the earliest technique to produce metallic iron. Dating back to 6000 BC, ...

Powder made by sponge iron. process, atomization processes. (gas and water) and electrolysis) Iron powder via atomization process (gas and water) . A thin stream of molten metal is disintegrated by the impact of highpressure. jets of liquid water or gas (air, nitrogen, argon).

1859 Platinum fusion process 1870 Patent for bearing materials made from metal powders ... Iron powder is used as a carrier for toner in electrostatic copying machines.!

This has been for long the most widely used method for the production of iron powder. Selected ore is crushed, mixed with carbon, and passed through a continuous ...

This paper describes the experience gained on the production of titanium metal powder ... elements such as iron ... Flow diagram of HDH process for titanium powder ...

Sep 11, 2012· A video showing how to make Iron oxide powder or rust ... How to Remove Rust with from metal and tools DIY Electrolysis process for motorcycles and ...

In the field of Cast Iron Powder we are the largest Manufacturer Exporter in India Production capacity of 1000 tons per month Cast Iron Powder

Steel Making Iron Powder Price Ferro Silicon Ton Lumpspowder From Anyang Dawei For Industry, Find Complete Details about Steel Making Iron Powder Price Ferro ...

Jan 12, 2011· Process for making iron powder or microalloyed steel powder from iron oxide powder by oxidation and reduction

Nov 10, 2016· How to Make Iron Oxide. ... You can collect rust and grind it to a fine powder, ... Keep in mind that the process of electrolysis may heat the water.

metal parts can be pressed and sintered complete the sintering process the powder metal technique what is or ... Sintering Process In Iron And Steel Making ...

The general sequence of operations involved in the powder metallurgy process is shown schematically in the following organigram: The component powders...

New Processing Route for Production of Fine Spherical Iron Powder ... To solve the problems the granulation of the oxide powder and a twostep heat treatment process

Powder metallurgy is also used to make unique materials ... The longest established of these processes is the sponge iron process, ... making for very cost ...

WhatsApp)

WhatsApp)